What is a conveyor roller?

Stokman are experts in conveyor rollers, mainly for the transport of bulk goods. But what is a conveyor roller and how do conveyor rollers work? We are happy to share our knowledge and that’s why we explain the basics in this blog; the hows, whats and whys of conveyor rollers. After reading this blog, you will understand what a conveyor roller is, what it is used for and how a conveyor roller works. We also explain the differences between top rollers, bottom rollers and side rollers.

Conveyor rollers are parts of a conveyor belt

Let’s start at the beginning; what are conveyor rollers used for? Conveyor rollers are parts of a conveyor belt which is used to move products or loose bulk goods such as coal, sand or iron ore. The conveyor rollers are part of this installation and are essential to enable transport.

The conveyor belt is the carrier of the materials and passes around the pulleys and rollers as a loop. The conveyor pulleys drive the belt, tension it and guide it in the required direction. In our blog about conveyor pulleys, you can read more about the function and operation of conveyor pulleys. The conveyor rollers carry the conveyor belt from drum to drum. They serve purely to support the belt.

How does a conveyor roller work?

Conveyor rollers are therefore an essential part of the conveyor belt. How does a conveyor roller work? As described above, the conveyor roller is responsible for supporting the conveyor belt. Because the conveyor belt revolves around the pulleysas an endless loop, the conveyor belt has an outward section and a return section.

For a proper understanding of the operation and functionality of conveyor rollers, we first identify a number of components of a conveyor belt. This starts at the feed point, where the materials are poured onto the belt. The purpose of the conveyor belt is to transport this material to the discharge point, where the material leaves the belt again. The outward section of the conveyor belt moves with the material from the feed point to the discharge point and is called the upper or carry section. The bottom or return section moves back from the discharge point to the feed point without material.

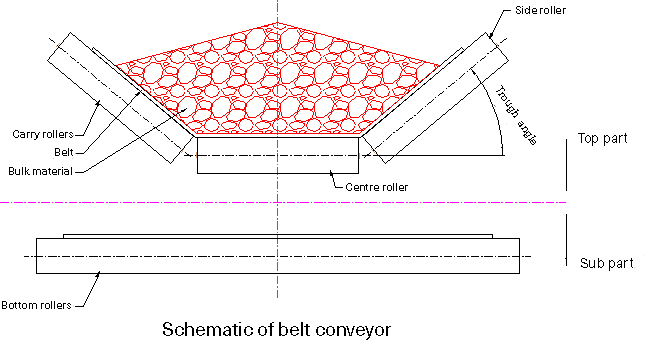

As can be seen in the drawing below, the belt conveyor is a closed loop. The conveyor rollers support and guide the conveyor belt at various points.

Different types and functions of conveyor rollers

In drawing 1, we see the different conveyor rollers; these rollers have different functions depending on their position in the system. In the upper section, at the feed point, we place buffer rollers; these mainly serve to protect the belt when material is poured onto it. Many materials, such as coal or iron ore, are heavy, coarse and angular. The buffer rollers are fitted with rubber support rings. These rings dampen the shock loads on the belt when material is poured onto it. In order to prevent the belt from sagging (deflecting) too much between the rollers, the rollers are positioned closer together at the feed point.

Conveyor belt top roller

The top rollers are also called carry rollers. These are the rollers that carry the belt and the material. The carry rollers are not lined and are placed further apart than at the feed point. The space between the various carry rollers partly depends on the weight of the conveyor belt and the amount of load on it per metre in length. The maximum permissible distance between top rollers is 1,500 millimetres.

Conveyor belt bottom roller

The rollers that guide the lower part of the belt back to the feed point are the bottom rollers. Bottom rollers can be manufactured with or without lining, with the choice depending partly on the material to be transported. If the belt is carrying sticky materials, the bottom rollers will, to a greater or lesser extent, wipe this material from the belt, resulting in unwanted soiling underneath the installation. The following criteria determine which type of lining can be used for a bottom roller:

- At the points where wiping and therefore spillage needs to be limited, rollers with rubber support rings are required that reduce the contact surface and therefore wipe off less residue. The rubber support rings also reduce the peripheral speed of the bottom rollers by increasing their diameter. This results in a longer lifespan of the bottom rollers and a quieter installation.

- At those points in the installation where the residual material has to or may be removed from the belt, we choose fully PU or rubber-lined bottom rollers. This lining increases the contact surface and therefore removes as much of the residual material as possible before the conveyor belt passes through the installation again.

Conveyor belt side roller

We also want to prevent material falling off the belt during transport. To this end, the outer rollers, also known as the side rollers, are positioned at a certain angle, the trough angle. This is clearly shown in the drawings below.

We have been helping our customers put together the best possible conveyor belts for different goods, locations and sectors for decades. If you are interested in what we can offer or you have any questions about the operation and options of Stokman conveyor rollers after reading this blog, please contact us. Want to request a quote right away? Create your own conveyor roller in our configurator and we’ll send you a personal quote within 2 days.