Description

The vibratory feeders from Machinefabriek Stokman are durable, energy-efficient, and perfect for precise transportation and dosing of materials like sand and gravel.

Advantages

- Efficient transport

- Precise dosing

- Durable

- Energy-efficient

- Versatile

Product information

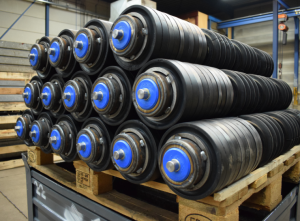

Vibratory feeders are effective tools in bulk handling systems. They are used for transporting and metering materials such as sand, gravel, and coal. These feeders are often made of metal or plastic and operate through vibrations generated by a vibration motor, vibration magnet, or an imbalance shaft. These vibrations enable efficient transportation, spreading, separation, and highly accurate metering of materials. By adjusting the speed and the amount of material, vibratory feeders can be perfectly tailored to the specific requirements of each project. Additionally, vibratory feeders can be equipped with extra features such as weighing systems, dust extraction, wear-resistant lining, or special shapes for spreading or separating products. This makes vibratory feeders ideal for applications where precise metering is required.

Product properties

Reducing maintenance

Machinefabriek Stokman’s vibratory feeders are easy to maintain, ensuring your production does not stop. The key components are easily accessible, allowing you to quickly and easily conduct inspections and maintenance. The feeders are made from durable materials, reducing wear and tear and the need for maintenance. Should anything break, we can quickly supply spare parts.

Steady Material Flow

A vibratory feeder doses material at a constant rate onto the conveyor belt. This is perfect for tasks where accuracy in dosing is important. This leads to higher productivity and a longer lifespan of the conveyor belt.

Long lifespan

Stokman produces top-quality vibratory feeders. These feeders are made with modern techniques and durable materials. They last longer and require less maintenance eventually saving time and money. Our vibratory feeders are also energy-efficient and can withstand extreme conditions. This makes them suitable for various industries and applications.

Damage analysis services

Damage to your vibratory feeder? Thanks to our intuitive inspection solution, we can locate the problem in no time. Simply upload a photo of the damage. Thanks to the detailed blueprint that we have of your system, we can analyze the situation quickly and accurately. We ensure that your vibratory feeder will soon function optimally again.

Get in touch!

Stokman stands for quality. In our machine factory in Raamsdonksveer we develop and produce conveyor belt rollers, pulleys and systems. We are also your partner in installation, maintenance and inspection in medium and heavy duty conveyor belt systems.

+31 162 51 60 40