Description

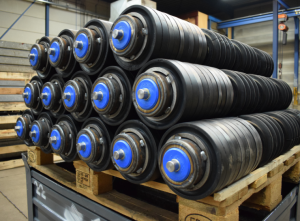

The durable and custom-made trough sets from Machinefabriek Stokman extend the lifespan of the conveyor belt, prevent spills and increase your production.

Advantages

- Efficient bulk transport

- Sustainable design

- Prevents spills

- Customization possible

- Saves maintenance costs

Product information

Troughs sets are important in transport systems for transporting loose bulk goods such as sand, gravel, coal or ore. Due to their unique design, with multiple rollers forming a trough, they support the conveyor belt and the material. This extends the life of the conveyor belt, prevents spillage of valuable bulk material and saves you on maintenance costs. By preventing spills, troughs also ensure that no bulk material ends up between moving parts. Machine Factory Stokman can make the trough sets for your transport system completely tailor-made. They are available in both fixed and adjustable models and in different materials such as steel or rubber. Installation and maintenance are simple, keeping your production running smoothly. To increase durability, our trough sets are hot-dip galvanized as standard, which protects them against rust, even in humid environments. Optionally, they can be sprayed or powder-coated in any desired color, so that they match your corporate identity. These additional finishing options not only provide visual added value, but also provide an extra layer of protection.

Product properties

Top roll supports and bottom roll supports

These supports provide extra stability and support to the conveyor belt. Top roll supports are placed on top of the trough sets and help distribute the load, while bottom roll supports are placed under the trough sets for extra load-bearing capacity and stability.

Side guide supports

Side guide supports ensure precise guidance of the conveyor belt. They prevent the tire from moving sideways. This is important for maintaining efficiency and minimizing wear.

Negative roller supports

A negative roller support is used to correct the belt steering. This support places a slight counter-pressure on the belt, correcting any deviations in the course of the belt and keeping the belt centered.

Damage analysis service

Damage to your trough sets? Thanks to our intuitive inspection app, we can locate the problem in no time. Simply upload a photo of the damage. Thanks to the detailed construction drawing that we have of your system, we can analyze the situation quickly and accurately. We ensure that your trough sets function optimally again soon.

Contact us!

Stokman stands for quality. In our machine factory in Raamsdonksveer we develop and produce conveyor belt rollers, pulleysand systems. We are also your partner in installation, maintenance and inspection in medium and heavy duty conveyor belt systems.

+31 162 51 60 40