Description

Machinefabriek Stokman’s magnetic conveyor belts ensure safe, clean and reliable production processes by effectively removing metal contaminants.

Advantages

- Efficient

- Trustworthy

- Easy to maintain

- Energy efficient

- Versatile

Product information

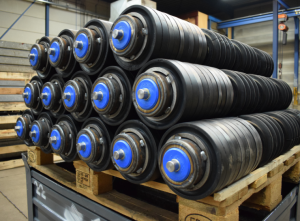

A magnetic conveyor belt ensures that ferrous contamination (contamination by iron and other metals) is removed from your bulk goods. This leads to better quality and a cleaner and safer production process. These metals end up in your bulk goods due to traces of iron ore or wear of machine parts during processing. Iron can also end up in the bulk material through contact with tools, equipment parts or even metal dust from the air. You can combine your existing conveyor belt with a strategically placed magnetic separator that separates the metals from your bulk goods. Overbelt magnets are powerful magnets that are placed above the conveyor belt. These attract and remove the ferrous components as they move underneath. A magnetic drum separator is located at the end of the conveyor belt. This rotating drum with a magnetic core separates ferrous materials as they flow over the surface. By eliminating iron contamination, you protect your bulk handling systems. This prevents costly downtime and repairs caused by iron fragments. In addition, you ensure iron-free bulk handling products by removing unwanted metal and ensuring an uninterrupted material flow and increased efficiency.

Product properties

Reduced maintenance requirements

The use of high-quality, robust materials increases the durability and minimizes wear of magnetic conveyor belts. The construction that provides easy access to components allows quick checks. This contributes to the early detection of possible problems. In the event of malfunctions, the fast and effective service of Machinefabriek Stokman ensures a solution.

Limitation of disruptions

Thanks to the superior quality and the application of progressive technologies, the magnetic conveyor belts from Machinefabriek Stokman guarantee reliable operation. This significantly reduces the risk of machine downtime.

Noise reduction

The magnetic conveyor belts have been specifically developed to limit the amount of friction and wear. This results in a significant reduction in noise pollution. The easy maintenance options also lead to lower noise production. This complies with the set noise standards and creates a more pleasant working environment for the staff.

Damage analysis service

Damage to your magnetic conveyor belt system? Thanks to our intuitive inspection app, we can locate the problem in no time. Simply upload a photo of the damage. Thanks to the detailed construction drawing that we have of your system, we can analyze the situation quickly and accurately. We ensure that your magnetic conveyor belt system function optimally again soon.

Contact us!

Stokman stands for quality. In our machine factory in Raamsdonksveer we develop and produce conveyor belt rollers, pulleysand systems. We are also your partner in installation, maintenance and inspection in medium and heavy duty conveyor belt systems.

+31 162 51 60 40