Description

The self-discharging systems on dredging ships from Machinefabriek Stokman enhance efficiency, safety, and sustainability in unloading materials such as sand, gravel, and sludge.

Advantages

- Unloading speed 4,500 tons/hour

- Long lifespan

- Less maintenance

Product information

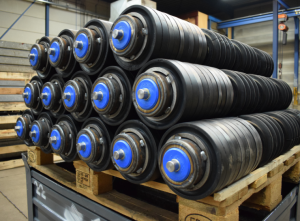

Self-discharging systems for dredging ships play a crucial role in unloading materials like sand, gravel, and sludge. These autonomously functioning systems perform more efficiently and consistently than conventional methods because they are not dependent on human interaction. Another significant advantage is increased safety: no crew is needed on the cargo, which reduces the chance of accidents. However, there are still challenges, such as wear due to salt water, swell, and wave action. Machinefabriek Stokman takes these factors into account in the design by using durable materials like polyurethane in conveyor belt rollers. The shafts of our conveyor belt pulleys are extra protected against salt water by special covers and are therefore easy to replace. These measures reduce unplanned downtime of your self-discharging system, ensuring no valuable production time and loss of money.

Product properties

Reducing maintenance

The wear-resistant materials we use for your self-discharging systems ensure less maintenance and a longer lifespan. Parts are also easily accessible, enabling quick inspections. If a part breaks, rapid service of Machinefabriek Stokman is guaranteed. We supply high-quality replacement parts so you can resume your dredging operations as quickly as possible.

Preventing downtime

Machinefabriek Stokman creates energy-efficient self-discharging systems using sustainable materials and modern techniques. Our pulleys and rollers are of top quality and ensure reliable operation. Our self-discharging systems typically last for 10 years, are thoroughly tested, and come with a 3-year warranty. This ensures our products are the best in their class.

Reduction of noise level

Machinefabriek Stokman specializes in designing self-discharging systems with low noise levels. We achieve this by making the maintenance of the systems as simple as possible, thus reducing friction and wear with associated vibrations. Additionally, we use materials that insulate sound and special coatings on the metal parts to further limit noise.

Damage analysis service

Having problems with your self-discharging system? With our convenient inspection solution, you can quickly identify the issue. Take a photo of the damage and send it to us. We have a detailed blueprint of your system, allowing us to accurately assess the situation. We ensure your self-discharging system is up and running as soon as possible.

Contact us!

Stokman stands for quality. In our machine factory in Raamsdonksveer, we develop and produce conveyor belt rollers, pulleys, and systems. We are also your partner in installation, maintenance, and inspection of medium and heavy-duty conveyor belt systems.

+31 162 51 60 40