Description

Machinefabriek Stokman’s bucket wheel excavators combine efficiency, versatility and ease of maintenance with exceptional reliability and minimal downtime, even in extreme conditions.

Advantages

- Efficient

- Trustworthy

- Easy to maintain

- Energy efficient

- Versatile

Product information

Machine factory Stokman’s bucket wheel excavators are mainly used in the mining industry to process raw materials such as lignite, sandstone and iron ore. These machines consist of a large wheel with several buckets. They move thousands of tons of material per hour, which they then transfer to conveyor belts, such as plate belts or dosing belts, for further processing. Our bucket wheel excavators also work seamlessly with our other products, such as hoppers with metering valves and pulverizers to transport and filter bulk materials. Machinefabriek Stokman’s bucket wheel excavators are distinguished by their ease of maintenance and reliability, even under extreme conditions such as large temperature differences. This ensures minimal downtime and maximum productivity. Their versatility also makes them suitable for projects outside mining, such as sand and gravel excavation, dike construction and self-unloading systems on ships.

Product properties

Easy to maintain

Mining sites are often remote and difficult to access, making the supply of spare parts challenging. Machine Factory Stokman’s bucket wheel excavators are wear-resistant, durable and guarantee minimal downtime. Parts are quickly accessible for inspections and maintenance. In the event of defects, Machinefabriek Stokman guarantees a fast delivery of spare parts to get your production going again.

Long lifespan

Stokman’s high-quality bucket wheel excavators are produced with modern techniques and durable materials. They require less maintenance and are energy efficient. Their long lifespan and resistance to extreme conditions not only save time and money, but also make them suitable for various sectors and applications.

Reduction of noise level

Machinefabriek Stokman produces bucket wheel excavators with a lower noise level. We achieve this by simplifying maintenance, thereby reducing friction and wear. In addition, we use sound-insulating materials and special coatings on metal parts to further minimize noise. This ensures a pleasant and quiet working environment for your staff.

Damage analysis services

Damage to your bucket wheel excavator? Thanks to our intuitive inspection solution, we can locate the problem in no time. Simply upload a photo of the damage. Thanks to the detailed blueprint that we have of your system, we can analyze the situation quickly and accurately. We will ensure that your bucket wheel excavator will soon function optimally again.

Contact us!

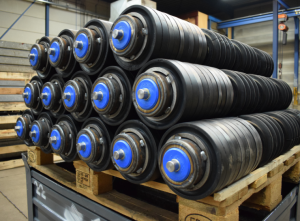

Stokman stands for quality. In our machine factory in Raamsdonksveer we develop and produce conveyor belt rollers, pulleys and systems. We are also your partner in installation, maintenance and inspection in medium and heavy duty conveyor belt systems.

+31 162 51 60 40